Consumer Mentor is reader-supported. We may earn commission on sales through our links at no extra cost to you.

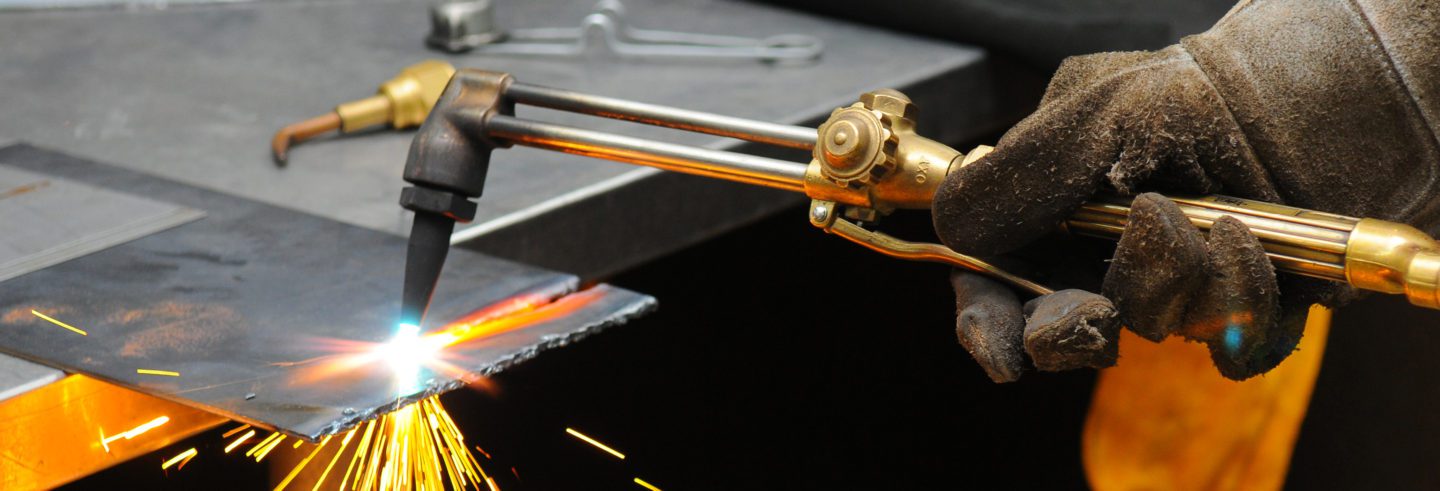

Thinking of purchasing a cutting torch but not sure what to look for? Whilst usually not used on a daily basis, cutting torches are essential for cutting, heating, welding, and brazing. There are a wide range of cutting torches available and the quality and reliability of these tools can differ considerably.

Working with gas can be dangerous and it is important to ensure that all safety concerns are considered. In this article, we go over the process and the equipment required, we offer you advice on choosing the right cutting torch, we discuss safety issues, and we review four of the best oxyacetylene cutting torch kits available.

Oxyacetylene welding and cutting

Oxy-acetylene welding and cutting are the oldest welding and steel cutting methods around. They also provide one of the least expensive setups in any workshop. A competent operator can heat, weld, silver solder, braze, or cut with this equipment. The system makes use of a controlled flow of oxygen and acetylene to weld, heat, or cut metal. Although arc welding has generally replaced the use of oxyacetylene in most industrial applications, it is still widely used in home-based workshops.

The equipment required

- Oxygen

- Acetylene or another fuel source

- Twin flexible hoses used to lead the gases to the nozzle which has a mixing chamber where the gases are combined to feed the flame.

- Regulator – the operator uses needle valves to regulate the flame and these will only work under the pressure is constant. The regulator ensures that the pressure remains constant as the gas level in the bottles drops.

- Flashback arresters

- Torch

- Nozzles

- Igniter

- Personal safety equipment

The Oxyacetylene Cutting Process – How it Works

Most oxyacetylene kits will come with both welding and cutting torches. The cutting torch has an oxygen blast trigger, the welding torch does not. The cutting torch is first used to heat the metal to the correct temperature and then the oxygen-blast trigger is engaged, and pure oxygen is poured onto the molten metal. The oxygen forms iron oxide and the heat created by the metal causes the metal to flow away from the cutting zone. Iron oxide residue can be removed from the metal by grinding it off. Only steel and carbon steel can be cut with a cutting torch.

What to look for in a cutting torch

Cutting torches come in a wide range of prices and, as can be expected, the price largely reflects the quality of the components and ultimately what is included in the kit. Before you find the right cutting torch, you should determine how frequently and for what purpose you require the equipment. Listed below are some of the characteristics that you should consider when purchasing a cutting torch kit.

- How is the torch rated? What thickness can it cut and weld?

- Does it have a heating or rosebud nozzle? Remember, you can only use this feature if you have large gas cylinders.

- What components are included in the kit? Some kits do not include gas lines, flashback arrestors, welding glasses, regulators and igniters

- How many tips are included? Tips can be expensive and the purchase of additional tips should be factored into the cost.

- How easy is it to change the tips? Can the change be accomplished without the use of tools?

- Are the components made from durable and corrosion resistant materials?

- The weight and balance of the torch

- The ergonomics

- the handle grip,

- position and size of regulators

- angle of the torch

- position of gas valves. Remember you will have to control these with leather welding gloves which could make for awkward handling.

- Warranty

- Special features such as hole free cutting, rotating tips, regulator seals

- You may want the security of owning a product backed by a well-known brand. There are several products backed by manufacturers that have been in the business for decades.

Getting Started

To start-off, your cutting torch instruction manual should give you the settings for the oxygen and acetylene. If it does not, start with a setting of 5psi on the acetylene and 20psi for the oxygen. Use the acetylene valve to adjust the flame, but proceed slowly and carefully as a small movement of the valve can make a big difference to the size of the flame. You do not need a large flame to effectively cut metal. When correctly set there should be no black soot emanating from the flame.

Ensure that when you start to cut the metal the slag falls safely.

With the right size tips, the right gas pressures, and artful practice, you will master the art of cutting. The tip should match the thickness of the steel. The centre hole is the cutting tip. The others are pre-heat tips. There is no industry standard for the cutting tip so you may have to consult the different manufacturers’ catalogues for sizes and then match the tip to the thickness of the steel that you plan to cut. The tip design will also differ according to the fuel that you plan to use.

Read this for more information on the safe use of your cutting torch

Safety Issues

Gas is dangerous if not properly fitted and handled. Before you set up your gas cylinders, ensure that you know what you are doing. Consult expert sources. Below are some useful safety tips:

- Gas cylinders should be chained at all times. If one falls over it can become a missile.

- When moving an oxygen cylinder, it should always have its valve screw on. If the valve gets knocked off it will take off like a rocket and will even penetrate walls.

- Acetylene is explosive and either end of both hoses must be equipped with flashback arrestors and/or check valves to ensure that there is no backflow of oxy-acetylene into the pipes or the cylinders which could result in the gas detonating.

- Oxygen under high pressure is dangerous in the presence of oil or grease and should always be kept away from flammable substances.

- Use a striker to ignite the flame as matches or lighters are not safe.

- Acetylene is highly volatile and is kept stable by the presence of acetone. It is for this reason that the cylinder must always be kept upright. If it has been lying on its side it must not be used until it has been standing for the same period that it lay on its side.

- Welding goggles should be worn at all times whilst using the welding or cutting torch. This is to protect your eyes from exposure to glare and from sparks. Welding glasses also make it possible for the operator to see the flame properly.

- Wear cotton clothes that are clean, hemmed and tightly woven. Synthetic materials such as nylon are not suitable as the easily catch alight.

- Wear leather gloves to prevent burns.

- Ensure that you wear closed, leather shoes when cutting as the slag can cause injuries

Our Picks for the Top 3 Cutting Torches – Reviewed

1. Goplus 10 PCS Oxygen & Acetylene Welding & Cutting Torch Kit Welder Tool Set w/ Case

This is a good choice for those who are looking for an incomplete set as the kit does not include the hoses, flashback arrestors or regulators.

With this product, you can cut, weld, solder or braze. The kit includes three copper welding nozzles and a cutting nozzle, along with the torch body and igniter. It is packed in a molded plastic case for easy storage and portability. The components are all made from durable brass and copper components.

The set is compatible with Victor cutting and welding nozzles.

2. Victor Technologies 0384-2045 Performer Medium Duty Cutting System, Acetylene Gas Service, ESS3-15-510 Fuel Gas Regulator

This cutting torch kit includes oxygen and acetylene regulators, a cutting tip, a heating tip, and a welding nozzle. The torch handle has built-in flashback arrestors and reverse flow check valves. It also has a striker, tip cleaners and shade 5 welding goggles. The T grade hoses are also included.

This heavy duty cutting torch can cut up to 3/4” steel. With the purchase of optional tips, this can be increased to up to 8”. The lightweight torch has great balance and is easy to adjust.

This is a great starter kit, but it does only come with one welding tip. The cutting tip is size 0 and the heating nozzle is size 4. The torch handle is angled at 90°.

The trademarked Edge Series regulators are ergonomically positioned for easy adjustment. They are made of brass and stainless steel and the regulator housing cap is made from an alloy of zinc and aluminium.

This product has a five-year warranty

3. Torch – Oxy-Acetylene Tough Cut Out

This full oxyacetylene welding and cutting kit contains just about all that you will need to get started cutting or welding in your workshop. Rated as medium to heavy duty, the cutting attachment is rated for 5/8” and the welding for up to 1/8”. Complete with cutting and welding torches, the pack also includes torch handle, acetylene and oxygen regulators, welding nozzles and cutting tips. The hoses also form part of the pack, as do the check valves and welding goggles.

The cutting and welding tips rotate a full 360° when ignited reducing hose resistance and entanglement. The Smith industrial grade regulators feature the trademarked Sure Seat technology. This filtering system prevents contamination in the seating area, reducing wear and tear.

The cutting valve is capable of starting keyhole free. Change the tips easily between jobs without the need for tools with the slip in tips. Each tip contains a mixing chamber for combining the oxygen and acetylene for maximum efficiency. The torches are constructed of brass and stainless steel, and the gauges have polycarbonate lenses. This product is made to last.

Miller Electric has been around since 1929 and is one of the world’s largest producers of arc welding equipment. The kit comes with a three-year warranty.

Conclusion

Finding the best cutting torch for you will be dependent on how you plan to use it and on your budget. The price range of the various products is vast. Taking into account the safety issues when working with volatile substances, the quality of the product should be a major consideration. Also, remember to factor in the number of nozzles included in the kit as this will affect the eventual cost.

Leave a Reply